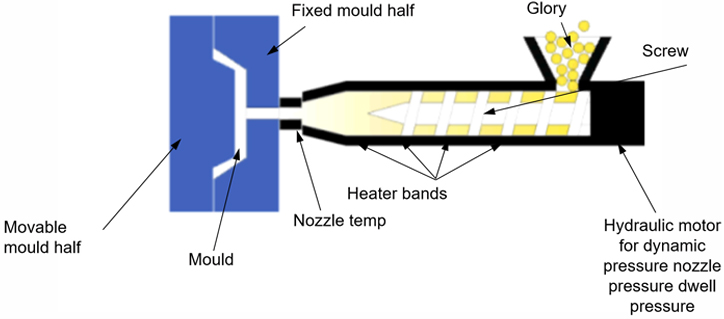

Injection moulding

As a general rule we work with standardized aluminium tool inserts of which a model is made in our own company by one of our injection moulding units. This results in quick completion of orders and the fastest possible processing time.

Filigree and large components in all common serial materials (thermoplastics) are producible within a very short time. Moreover, 2K components with subsequent installation, as well as surface structures according to DIN VDI 3400 are possible. 20 - 1 000 units are the typical batch sizes of unloading. 1 000 - 10 000 units are the typical batch sizes of master forms.

| ARBURG GmbH + Co KG - Allrounder 470 E Clamping force up to 100 t, injection weight of 100 g Number of systems: 2 |

| ARBURG GmbH + Co KG - Allrounder 520 E Clamping force up to 150 t, injection weight of 140 g |

| ARBURG GmbH + Co KG - Allrounder 570 E Clamping force up to 200 t, injection weight of 360 g |

| ARBURG GmbH + Co KG - Allrounder 570 A Clamping force up to 200 t, injection weight of 620 g |

| Sumitomo-Demag - Demag IntElect 450-3000 Clamping force up to 450 t, injection weight of 1700 g |

|

A wide variety of all common thermoplastic series production material from different manufacturers with different material properties is available for injection moulding. Due to the fact that there is such a great variety of material we can offer you a detailed consultation. |

Battery Contact Cover for eBikes

The FAZUA team has developed an innovative eBike drive system aimed at pushing the limits of cycling mobility while also preserving the natural feel of a non-motorized bike. FAZUA was already assembling one version of a 2-element component (hard/soft) which was intended to be delivered to the clients. However, they realized there was a need for a further development that under such circumstances would have interfered with an on-time delivery. With ist Rapid-Tooling process, cirp’s support was decisive for FAZUA to maintain the commitment despite the “impossible” tight schedule: by doing a few decisive adjustments, the component was optimized in a way that made it possible in just one week to produce and sample an injection mold for the hard component and the matching mold-design for the soft one. Within this period of time, the first 1.000 units of this 2-element component were produced in-house out of a total of 15.000 that have been produced to date.

Project: cirp-EXPRESS 2K series tool in just one week

Material: 2-element component (hard/soft)

Copyright FAZUA GmbH

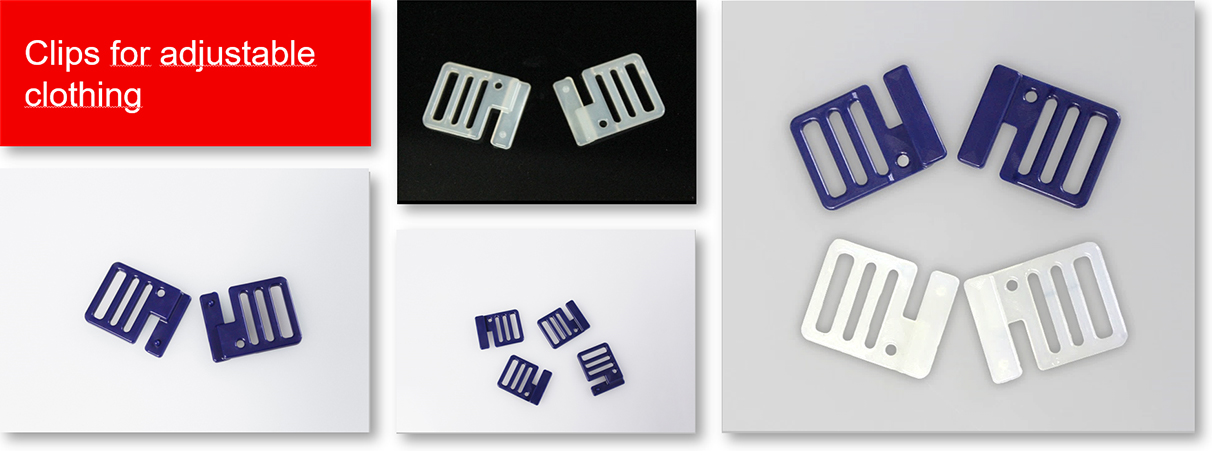

Clips for adjustable clothing

Individually adjustable product elements facilitate a comfortable fit for end consumers. Multiple rows of fasteners also help with adjustment, and help compensate for material fatigue. In its injection moulding machines, cirp is currently producing see-through and blue fasteners. The final position of the functional components can be set easily and securely thanks to a releasable clip connector. Contact with hot water, and washing in the washing machine, are no problem.

Copyright cirp GmbH

Industrial smart watch protective case

The Stuttgart-based start-up aucobo offers leading, person-centric, smart-wearable solutions for industrial Shop Floor Management. Thanks to the new form of networking between humans and machines, the automated and intelligent distribution of information allows for much more effective collaboration and end-to-end digitisation in production and logistics. The summarised information is transmitted directly to the wrist via the smart watch. A protective case reliably protects the end device against damage and dirt in the production units. As a project partner, cirp is helping the company to produce the case with its entire range of services, from 3D digitisation and design, and selecting the material and technology used, through to the finished product. The first prototype was made from TPU. The series-produced piece is currently being produced by means of injection moulding using a skin-friendly material.

Copyright cirp GmbH and aucobo GmbH